Remain Ahead of Deterioration: Important Upkeep Tips for Undercarriage Parts

Remain Ahead of Deterioration: Important Upkeep Tips for Undercarriage Parts

Blog Article

Important Guide to Undercarriage Components for Heavy Tools

When it comes to hefty tools, the undercarriage plays a crucial duty in making sure effective and smooth operations. From track chains to rollers and idlers, each element adds to the total functionality of the tools.

Significance of Undercarriage Parts

Recognizing the important role that undercarriage components play in the efficiency and long life of hefty tools is critical for efficient upkeep and procedure - undercarriage parts. The undercarriage parts create the foundation on which the whole equipment runs, sustaining the weight of the equipment, providing security, and taking in shock tons during operation. A properly maintained undercarriage not just ensures smooth operation however also contributes considerably to minimizing downtime and repair work expenses

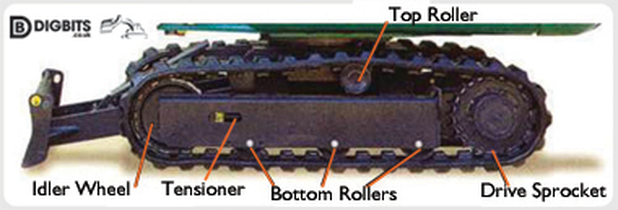

The undercarriage is composed of different necessary components such as track chains, track footwear, gears, idlers, rollers, and track frameworks. The track chains and track footwear aid in supplying grip and support, while the idlers and gears aid in driving the tracks efficiently.

Sorts Of Track Chains

Track chains are important elements of hefty equipment undercarriages, supplying the needed traction and assistance for reliable procedure. There are primarily two kinds of track chains used in heavy devices: sealed and oiled track chains (SALT) and dry track chains.

Role of Rollers and Idlers

Rollers and idlers play a vital duty in supporting and guiding the track chains of hefty devices undercarriages, adding to the total security and effectiveness of the machinery. Rollers are made to sustain the weight of the equipment and supply a smooth surface area for the track chain to relocate along. They help disperse the weight uniformly, decreasing excessive endure the track chain and making certain correct grip. Idlers, on the other hand, overview the track chain and aid keep correct tension throughout the undercarriage system. By directing the track chain in a regulated manner, idlers stop excessive side-to-side motion, reducing the danger of derailment and irregular wear.

Together, idlers and rollers operate in harmony to guarantee that the track chain remains in place, also on rough terrain, boosting the equipment's efficiency and durability. Correct upkeep and regular assessment of rollers and idlers are More Info important to prevent early wear and possible failures, eventually maximizing the performance and her comment is here life expectancy of heavy equipment undercarriages.

Comprehending Sprockets

One essential facet of sprockets is guaranteeing appropriate placement and tension to stop premature wear and damages. Misaligned sprockets can create irregular wear on the track chain, causing decreased performance and possible safety and security dangers. Routine maintenance and assessment of sprockets are important to determine any signs of wear or misalignment immediately.

Additionally, gears come in numerous sizes and tooth setups, depending on the details heavy devices and its designated usage. Appropriate selection of sprockets based upon the devices's specs is important to make certain optimal performance and durability of the undercarriage system. Understanding the duty of gears and their maintenance needs is crucial for making the most of the effectiveness and life expectancy of hefty tools undercarriages.

Upkeep Tips for Long Life

To make sure the extended sturdiness and optimal capability of hefty equipment undercarriages, diligent upkeep methods are crucial. Routinely checking undercarriage components such as track shoes, rollers, idlers, and sprockets for wear and tear is vital. Replace any kind of worn or damaged parts quickly to stop further damage to the undercarriage system. Correct track stress modification is also crucial for lowering early wear on undercarriage components. Over-tensioning can cause increased stress on the parts, while under-tensioning can trigger track slippage and accelerated wear. In addition, keeping the undercarriage tidy from particles build-up, mud, and various other impurities can help protect against corrosion and prolong the life expectancy of the components. Greasing the undercarriage parts at suggested periods will additionally Website reduce rubbing and wear. Finally, scheduling normal upkeep checks with trained specialists can identify prospective issues at an early stage and resolve them before they escalate, inevitably making the most of the longevity of hefty devices undercarriages.

Final Thought

In conclusion, undercarriage parts are essential elements for heavy devices, playing vital functions in keeping security and capability. Comprehending the different sorts of track chains, rollers, idlers, and gears is essential for correct maintenance and long life of the devices. By adhering to upkeep tips and on a regular basis inspecting and replacing used components, drivers can make sure the optimum performance and effectiveness of their heavy equipment. Correct treatment and attention to undercarriage components are vital to optimizing equipment life expectancy and productivity.

The undercarriage consists of various important parts such as track chains, track shoes, sprockets, idlers, rollers, and track frameworks. The track chains and track shoes aid in offering grip and support, while the idlers and gears help in driving the tracks efficiently (undercarriage parts). There are mostly two types of track chains utilized in heavy equipment: secured and lubricated track chains (SALT) and dry track chains. Proper choice and maintenance of track chains are critical to make sure the general performance and durability of hefty tools undercarriages

Gears are indispensable parts of hefty equipment undercarriages, liable for transferring power from the equipment to the track chain.

Report this page